Application in Production, Pharmaceutical and Food Industry

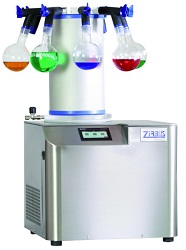

ZIRBUS TECHNOLOGY GMBH

Since its founding in 1984, ZIRBUS technology GmbH, as a German manufacturer, has gained an outstanding reputation on the

international market. We manufacture not only autoclaves but also focus on process technology. A steadily increasing number

of customers is putting their trust in Zirbus brand autoclaves and lyophilizers.

Our customers' satisfaction is our top priority...

- TOGETHER WITH OUR CUSTOMERS, WE CONTINUALLY DE V ELOP NE W SOLUTIONS FOR VARIOUS ARE AS OF APPLICATION

- WE TAKE ADVANTAGE OF EVERY POSSIBLE OPPORTUNIT Y FOR IMPROV EMENT

- PERFECTION IN SERVICE IS WHAT DRIVES US

- EFFICIENT AND RELIABLE TECHNOLOGY

- A PERFECT COMBINATION OF SOF T WARE AND HARDWARE

CERTIFIED QUALITY

- ASME certified

- Module H certified

- EN ISO 9001

The quality management (QM) system according to DIN EN ISO 9001 implemented and practiced at ZIRBUS technology GmbH provides the framework for our quality and cost oriented activities.

In addition, a risk management system is a component of the QM system.

THE RIGHT EQUIPMENT FOR YOUR NEEDS

|

PARAMETER |

SUBLIMATOR |

||||

|

EKS 10 |

EKS 30 |

EKS 50 |

EKS 100 |

EKS 150 |

|

|

Chamber diameter |

Ø600mm |

Ø800mm |

Ø1000mm |

Ø1200mm |

Ø1400mm |

|

Shelve size |

420x600mm |

500x900mm |

600x950mm |

800x1150mm |

900x1500mm |

|

Distance |

55mm |

55mm |

55mm |

55mm |

55mm |

|

No. of Shelves |

5 |

7 |

9 |

11 |

12 |

|

shelve area |

1,26m² |

3,15m² |

5,13m² |

10,0m² |

16,2m² |

|

Shelve temperature |

Vers. I -40…+60°C |

||||

|

Vers. II -55…+60°C |

|||||

|

Condenser capacity |

10kg/24h |

30kg/24h |

50kg/24h |

100kg/24h |

150kg/24h |

|

15kg total |

45kg total |

75kg total |

150kg total |

200kg total |

|

|

Condenser temperature |

Vers. I -50°C Vers. II -75°C |

||||

|

Dimensions |

L1500 x |

L1750 x |

L1900 x |

L2200 x |

L2500 x |

|

W980 x |

W1300 x |

W1500 x |

W1700 x |

W1900 x |

|

|

H1850 |

H1850 |

H1950 |

H2050 |

H2150 |

|

Available options:

- Air or water cooled cooling systems

- Clean room design, surfaces Ra <0,8µm electropolished

- Product trays

- Oil free vacuum pump

- Stainless steel housing or wall integration

- Capacitive vacuum sensor

- Process visualization Scada

- Siemens / Mitsubishi PLC

- CIP (automatic cleaning)

Features:

- One chamber system, condenser behind the shelves

- Complete stainless steel 316L

- Liquid tempered stainless steel shelves for freezing and drying

- Radiation shelve on top position

- Uniform temperature distribution +/-1°C during freezing and drying

- Repeatable processes

- Integrated vacuum pump

- Industrial PLC control system with touch panel

- Free programmable receipts

- Integrated vacuum regulation

- Fast defrost by steam or hot water

SYSTEM SETUP:

- Drying chamber and components are build on one

- Stainless steel base frame.

- Stainless steel front panel made of AISI304

- This front panel is suitable for wall mounting.

- In the basic version the freeze dryer is unclad.

Drying chamber:

- Round drying chamber as one chamber system,

- The condenser is located in the same chamber.

- Dimensions: Ø 800 mm

- Volume: 900 Liter

- Material: Stainless steel AISI 316L (1.4404)

- Surface finish inside: stained and glass-beaded

- Leak rate of empty and dry chamber: <0.05mbar liter / sec.

- Achievable end vacuum with corresponding vacuum pump: <0.01mbar

Chamber door:

- Stainless steel hinged door with glass window.

- Including stainless steel door cover

- Door seal made of silicone

Measurement Technology:

- Vacuum sensor: Pirani vacuum sensor

- Range 0.001 ... 1000mbar

Temperature sensors:

- 3 flexible product probes PT100 diameter 4x30mm, silicone cable.

- Additional one temperature sensor for surface area and one for condenser temperature.

Controller :

- Mitsubishi FXN Industrial PLC

- 7 "color touch panel, Drytec " M "

- Drying programs: 20 pieces, freely definable

Program structure:

- 10 Freezing stages

- 10 Main drying stages

- 10 Post-drying stages

Shelves:

- Liquid-controlled shelves: -40 ... + 60 ° C

- Cooling floor: 1.0°C / min (in the range +20 ...- 30 ° C) For freezing and drying of products.

- Number of shelves: 7 pcs

- A radiation plate is located at top Material: Stainless steel AISI 316L Surface K120 polished

- Dimensions: 500 x 900mm Surface thickness: 15 mm Total shelves area: 3.15 m2

- Shelf distance: 55mm

- Shelves Flatness: +/- 1 mm per m

Ice condenser:

- The ice condenser is located behind the shelves

- Material of the cooling coil: Stainless steel AISI 316L / 316TI

- Cooled surface: 0.5 m²

- Capacity condenser: 30 kg / 24h

- Max. condenser capacity: 45kg

- Final temperature: -45°C (without load; in vacuum)

- Cooling time: + 20°C to -40°C approx. 15 minutes

- Fast defrosting by hot water or optional with steam

Cooling Systems :

- Air cooled refrigeration system consisting of a

- Reciprocating piston Compressor

- Engine power of the compressor: 0.75KW

- Refrigerant GWP1397 approved according to the latest F-gases

- Regulation

Vacuum control:

Automated isolation valve between condenser and vacuum pump for carrying out a vacuum control.